Analytical Balaneces

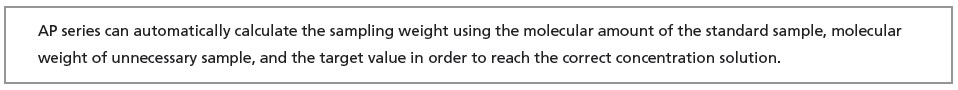

Product Features

Features

-

-

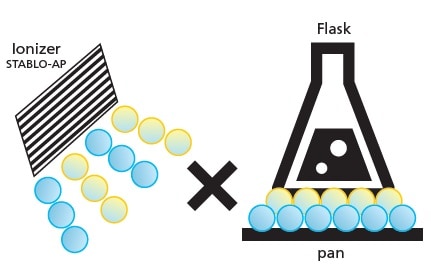

Stress Free – A variety of accessories and options suitable for semi-micro measurementsThe STABLO-AP ionizer can be mounted.

This eliminates the influence of static electricity, achieving reliable measurements in a simpler procedure. -

For Regulation-for the Pharmaceutical IndustryInterlocking with LabSolutions Balance enables compliance with a variety of regulations for measurement data integrity, including ISO 17025 for testing laboratories, ISO 9001 and ISO 14001 for the manufacturing industry, and GLP/GMP and the United States Pharmacopeia (USP) for the pharmaceutical industry.

-

-

-

And moreSmart Settings

Response and stability settings can be changed during measurements with a single touch.High Speed – Fast weighing response

High Speed -Fast measurement significantly improves operational efficiency

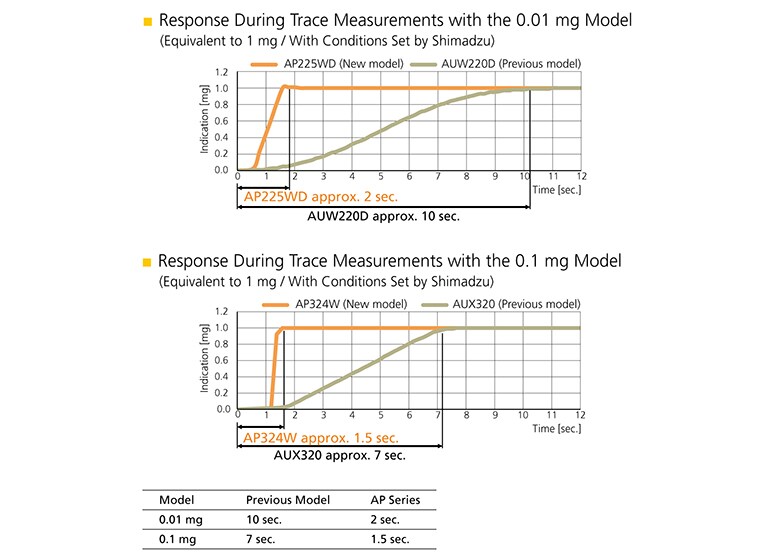

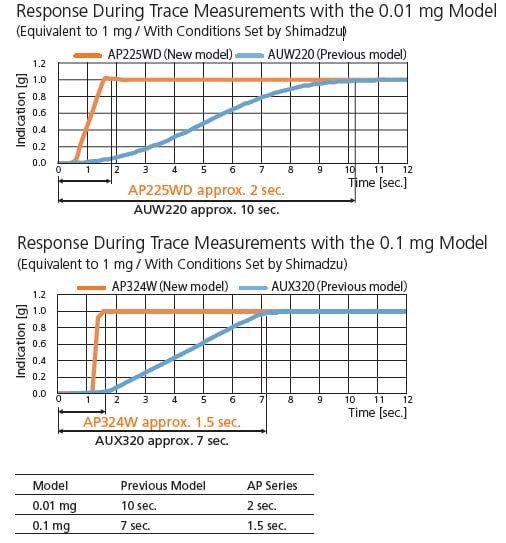

Fast Response with UniBloc AP Technology.

Shimadzu analytical balances boast a one-piece UniBloc weighing sensor, which is now even more advanced.

The response time is reduced to about 1/5 the time of previous models.

The improved UniBloc sensor offers a response time of just 2 seconds, an improvement from 10 seconds with the previous model.Stress Free – A variety of accessories and options suitable for semi-micro measurements

Built-in High-Performance Ionizer (Optional)

The ionizer eliminates influence of static electricity in 1/10 the time of previous models.

Note: Example of typical static electricity removal time (±1000 V → ±100 V) 1 sec. for STABLO-AP and 10 sec. for STABLO-EX

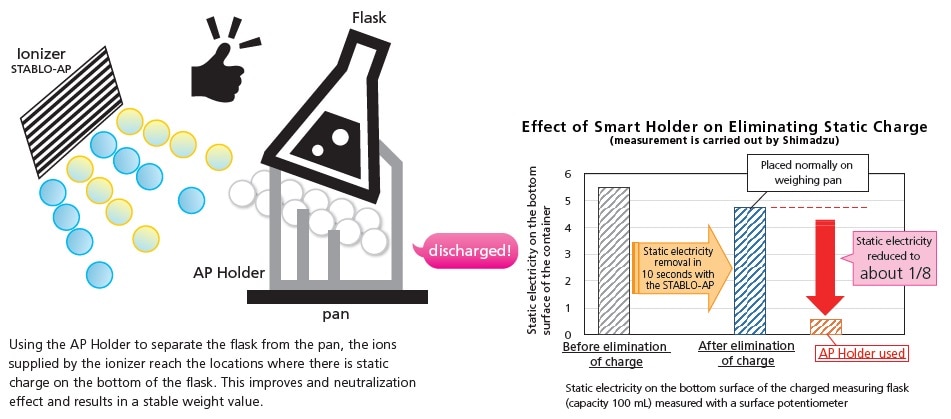

The AP Holder compatible with a variety of weighing containers is provided standard, and static electricity is properly removed from the bottom of the container, resulting in easier operation.

The AP Holder in combination with the ionizer can eliminate the infuence of static electricity on the weight value.

Container Applicable Volume (*) Volumetric flask 10 to 100 mL Conical flask 100 mL Beaker Centrifuge tube(Spitz tube)3 to 25 mL Test tube * About 70 mm or more height or length is required.Measurement of Samples Carrying an Electrostatic Charge

Effect of Samples Carrying Electrostatic Charges

Effects of static electricity -SPOON with powder

Why is the AP Holder needed as a countermeasure to static electricity?

If the AP Holder and the STABLO-AP ionizer are used together, static electricity can be quickly removed from the entire test chamber, including the surfaces of glass containers, which helps to decrease the weighing time and improve reliability.

NG The conical flask is directly placed on the pan.

The bottom of the flask is in close contact with the pan, so removal of the static charge is obstructed, leading to an unstable weight value.

The bottom of the flask is in close contact with the pan, so removal of the static charge is obstructed, leading to an unstable weight value.Ions emitted from the ionizer cannot reach the bottom of the flask, so removal of static charge from the bottom of the task is insufficient. Therefore, Coulomb forces act between the surrounding metal parts and the windshield door, which affects the weight value.

OK The conical flask is tilted using the AP Holder and placed on the pan.

The AP Holder can hold the container in a tilted position, so the charge can be reliably removed from the bottom of the container being mounted on the AP Holder.

Improving Weighing Efficiency and Removing Static Electricity From Analytical Balances

AP Series Advanced Performance UniBloc Balances

Faster Response and Higher Stability

Improved Response Time of AP series

-comparison with AU Series–

Ionizer Static Electricity Remover

Effects of Static Electricity

-Anti-static device recommended for balances-For Regulation-for the Pharmaceutical Industry

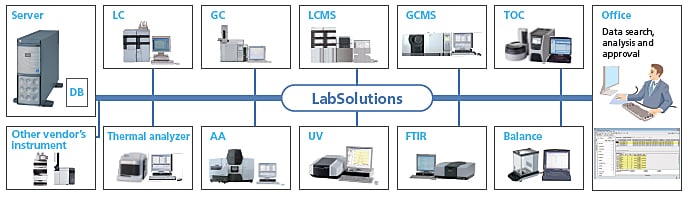

Solutions to Improve Operational Efficiency and Ensure Data Reliability LabSolutions Balance Analytical Network Data System Compliant with ER/ES Regulations

- Eliminate manual entry, and all the weighing data are saved automatically in a safe database without transcription mistakes.

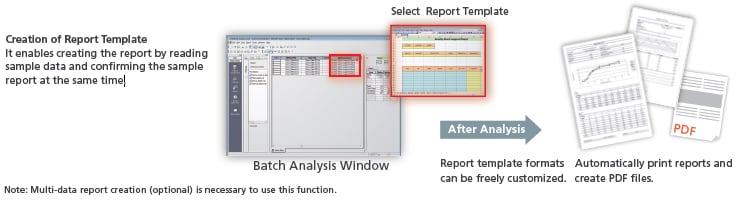

- Reports appropriate for weighing methods, such as the mass variation test, drying weight loss test and particle size test, can be created automatically after the measurement. In addition, customized reports featuring such information as system conformance, content uniformity and elution tests together with the analysis results obtained by HPLC, etc. can be created.

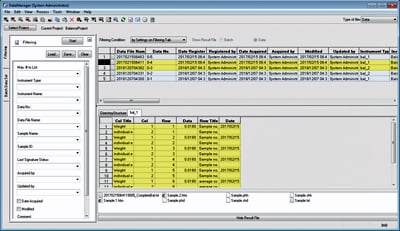

Main Window of LabSolutions Balance

Integrated Management of Analytical Data on Network System Using LabSolutions

Compliant with the Latest Data Integrity Guidance (U.S. FDA 21 CFR Part 11)

- Weighing results can be automatically saved in the database together with other information, including sample ID, operator name, operation date and series number of instrument used.

This enables quick data searching based on sample information. - It allows setting up user authority to ensure only the authorized user can create a template for weighing.

- It prevents improper manipulation, unintended overwriting and deletion of data. In addition, measurement results, all the operation histories and reasons will be saved in the database as log files.

Integrated Report Creation Function Combines Analysis Results from HPLC and Weighing Results from Balance

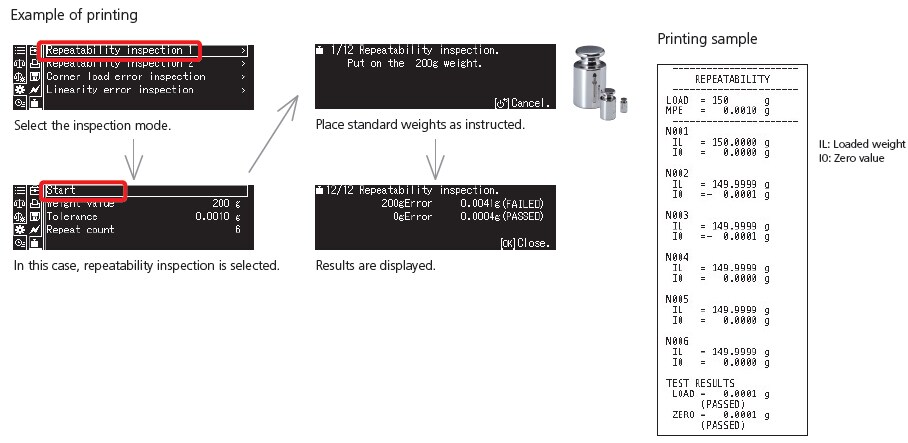

Periodic Inspection Support Function(AP-W/AP-X Series only)

AP series supports periodic inspections. The function allows inspection of repeatability, corner load error, and linearity by simply following instructions displayed on the screen.

For HPLC

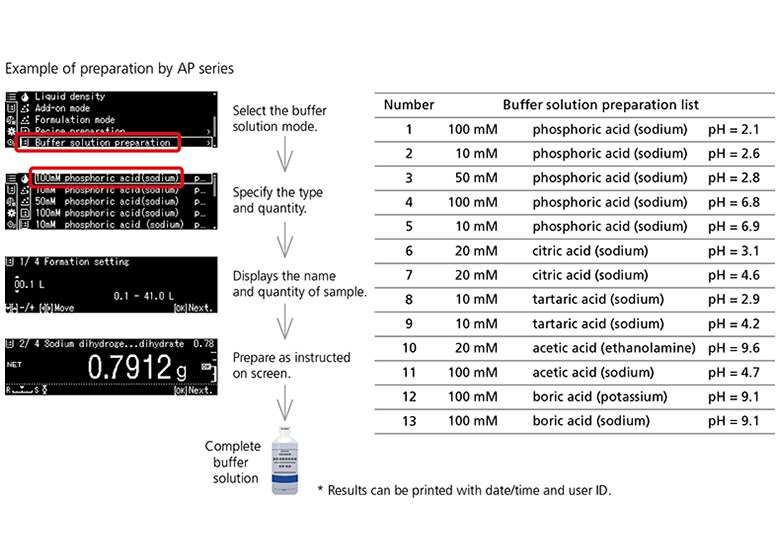

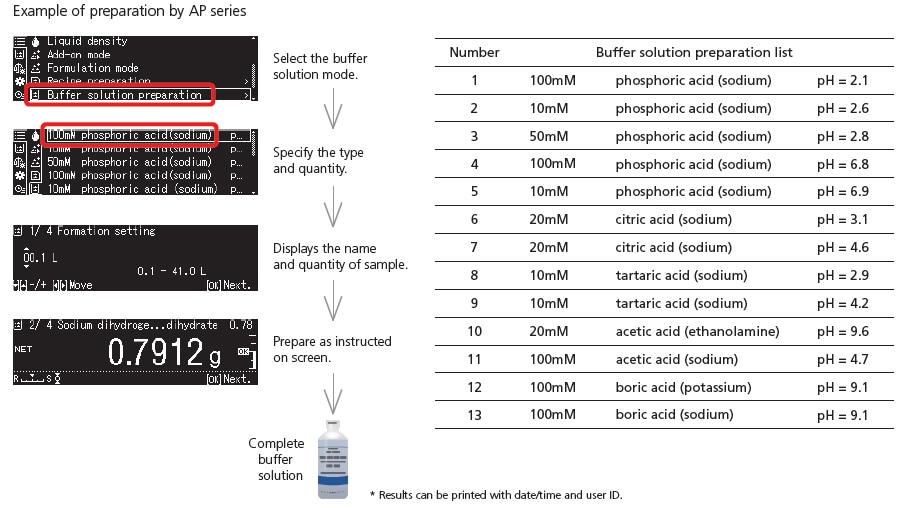

Buffer Solution Preparation Mode(AP-W Series only)

- Recipes for 13 commonly used buffer solutions are included as standard

Preparation recipes for commonly used buffer solutions are provided as standard.

e.g. disodium phosphate, sodium acid citrate - New buffer solution recipes can be registered

If a buffer solution is not registered by default, it can be newly registered. - Instructions are shown on the display

The target weighing value is shown on the display and analog bar in order to compare the target with the current weight. Manual calculation is not needed. - Record function

Record output with date, time and operator name.

- And more

The pH level of mobile phase (eluent) solutions used in liquid chromatographs is adjusted to improve separation of components and extend the life of columns. This pH adjustment process is performed using a buffer solution.

Currently, the most common method is using a pH meter to measure the pH as the solution is prepared; however, this process requires considerable time and effort, which can cause operational bottlenecks.

An alternative method does not require a pH meter. It involves preparing solutions by weighing fixed theoretically calculated quantities of an acid and base.

AP series supports weighing these acids and bases. If the type and quantity of the buffer solution are specified, the balance displays the type and quantity of sample that should be weighed. Then the buffer solution can be prepared easily by adding water to the specified quantity of sample weighed accordingly.Preparation example:

When weighing and preparing 50 mM of di-sodium hydrogen phosphate, 2-hydrate and 50 mM of sodium dihydrogenphosphate, 2-hydrate in order to prepare 3 L of 100 mM phosphoric acid (sodium) buffer solution at pH=2.1:

Buffer Solution Preparation

Recipe Preparation SETUP

Fast, easy registration of formulation recipesRecipe Preparation -OPERATION-

Fast, easy formulation from pre-registered database.Sample Preparation

Fast, easy preparation of analytical standardsSample Preparation(AP-W Series only)

When preparing a standard solution from a particular component, the standard powder for this component will be a hydrochloride or a hydrate.

Preparing a standard solution of the target component at a desired requires difficult calculations prior to weighing it. With the AP series, however, the required weight value is automatically calculated, so it can be weighed without performing manual calculations.Example of preparation by AP series

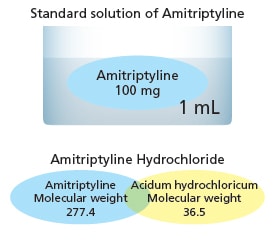

Standard sample of Amitriptyline is Amitriptyline Hydrochloride.

Calculation is essential to determine part of Acidum hydrochloricum by molecular weight in order to make a 100 mg/mL Amitriptyline solution. Molecular weight of Amitriptyline: 277.4

Molecular weight of Acidum hydrochloricum: 36.5

Molecular weight of Amitriptyline Hydrochloride: 277.4 + 36.5 = 313.9 To compare the molecular weight of Amitriptyline Hydrochloride with Amitriptyline, the following calculation is necessary. 313.9/277.4 = 1.132 The molecular weight of Amitriptyline Hydrochloride is 1.132 times of Amitriptyline. So, if 25mg of Amitriptyline is used, it follows that the weight of Amitriptyline Hydrochloride should be: 25 mg x 1.132 = 28.3 mg. Hence, 28.3 mg of Amitriptyline Hydrochloride is needed to make the correct standard solution.

Just weigh the target weight value on display and the target weight of the standard sample can be obtained.

Checking weighing conditions on the same display

Sample Preparation

When preparing a standard solution from a particular component, the standard powder for this component will be a hydrochloride or a hydrate.

Preparing a standard solution of the target component at a desired requires difficult calculations prior to weighing it. With the AP series, however, the required weight value is automatically calculated, so it can be weighed without performing manual calculations.For Regulation for the Pharmaceutical Industry

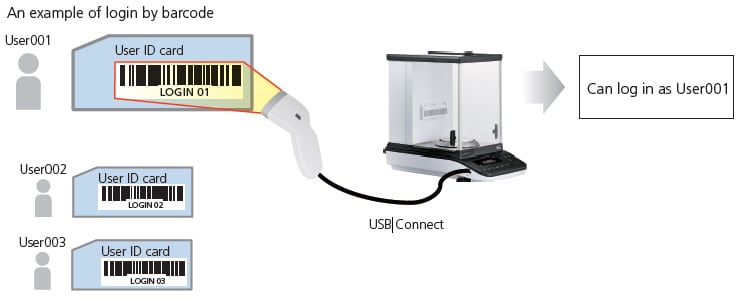

High-Security User Management

Operations can be kept secure with user ID and password protection. Access rights can be specified separately for each user to prohibit unauthorized actions such as performing calibration or changing the settings. User IDs can also be used for barcode management.

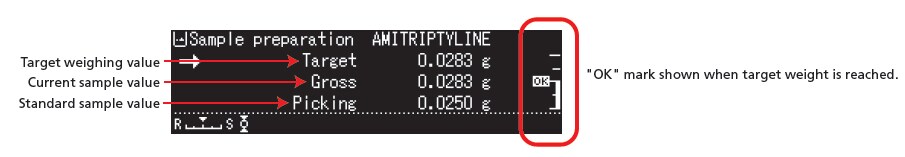

Printing Data in Accordance with Various Regulations

Printing can be customized to indicate when the measurements were taken and by whom. Users are free to set which items are to output, and in what order. The date, time, calibration log, and other information can be printed depending on the purpose of printing, which supports compliance with ISO, GLP, and GMP.

– Date

– Time

– User name

– Balance manufacturer name

– User ID

– Serial number– Balance ID

– Software version

– Minimum sample quantity

– Blank line

– Ruled line (——–)

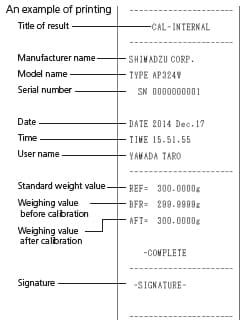

Minimum Measurement Value (Warning Function)

Reproducibility can be confirmed by repeatedly measuring weights as instructed by AP series. The minimum sample quantity is automatically determined from the standard deviation and recorded in AP series. If the minimum sample quantity requirement is not satisfied during measurement, an indicator flashes to warn the user.

Recipe Function (Achieve Your Preferred Compounding Process)(AP-W Series only)

Sample recipes can be registered, allowing users to simply follow displayed instructions. This is convenient when compounding medicines.

Save Your Operation

USB Offers Greater Expandability (USB host: AP-W Series only)

Equipped with an RS-232C connector, a USB device and a USB host as standard. You can now simultaneously send output to both a computer and printer or connect a USB flash drive, a barcode reader, or an external numeric keypad.

Transcription errors can be avoided and data can be recorded without a computer.USB flash drive

Connecting a USB memory device allows you to record large amounts of weighing data in CSV format. Used in combination with the interval output function, it also enables recording of long-term changes over time.

Example of a record:

File name

Date and time

Weighing value*The information saved will differ depending on the function used.

Balance Keys, Balance Data Collection Software

Easy-to-Read Organic EL Display

Because the pixel elements in the organic electroluminescence display emit light, the screen can be seen clearly even in dark locations.

Multi-language display capability*2 provides a more intuitive operating interface. A wider viewing angle has also improved the visibility of measurement values, which helps increase the efficiency of measuring operations.

*2 Japanese, English and Chinese

Display capture function

Weighing display can be recorded into USB memory in BMP format. User name, date/time, and setting can be shown with display information.

The user name, time, measurement conditions, pass/fail judgments, and other information displayed on screen can be saved as is, enabling the recording of measurements, and checks after measurements.

Numeric keypad

Connecting a common external numeric keypad makes it easier to enter numeric values. This is especially useful for entering the mass value of weights, setting upper/lower limit values for the comparator function, or entering the sample count during piece counting mode.

Barcode reader

A barcode reader can be connected. Simply reading a barcode makes it possible to input user ID/Password. It is possible to manage sample IDs using barcodes.

An ID and password are needed to log in to the AP series if protected access is activated. With the barcode, an operator can log in by scanning the barcode instead of inputting an ID and password. * The latest information can be seen from the Shimadzu website (/balance/)

And more

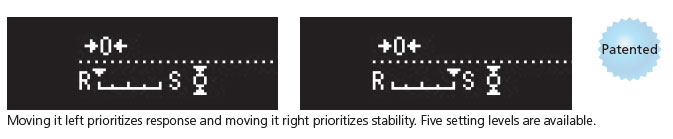

Smart Settings

Response and stability settings can be changed during measurements with a single touch. Changing the settings for different applications can make it even easier to use.

User-friendly arrow keysThe indicator is operated using the left and right arrow keys. Moving the setting toward [R] prioritizes response, which makes it easier to operate the balance. Conversely, moving it toward [S] makes it easier to stabilize weight values, which can improve readability in environments with vibration.

For Better Weighing Results: PSC and Clock-CAL

A Perfect Self Calibration (PSC) function is included. The analytical balance automatically detects any temperature changes that could affect sensitivity and automatically starts calibration.

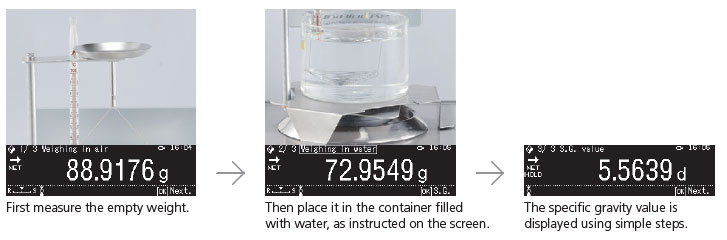

The Clock-CAL function enables automatic calibration at a pre-specified time (for example, before starting work, during lunch, or after work hours).Specific Gravity Measurement

In combination with an optional specific gravity measurement kit, the balance can be used to measure specific gravity. Operations are simplified by a text-based navigation function. By using sinkers, the specific gravity of liquid can be measured as well. This allows measuring the specific gravity of metals, rubbers, plastics, and other materials easily.

AP225W

Capacity 220g mol Conversion Function Included Display OEL display (dot matrix) Weight Approx. 7.9 kg Body Dimensions Approx. 212(W) x 411(D) x 345(H)mm

(power supply unit included)Pan Size ø91 mm Sensitivity Stability Against Temperature Range ±2 ppm/°C (10 to 30°C) Operating Temperature/Humidity Range 5 to 40°C 20 to 85% *5 Ionizer Optional Clock-CAL Included Inspection Support Function Included Sample (Concentration) Preparation Included HPLC Buffer Solution Preparation Included Minimum display 0.01 mg Recipe Compounding Included USB Device (Type B) Included USB Host (Type A) Included Response Time *4 8 sec. Response Time for race Measurements *3 2 sec. Linearity *2 ±0.1 mg Minimum Weight *2 20 mg Repeatability (Standard deviation) 0.015mg

(to 20g)

0.03mg

(to 100g)

0.05mg

(to Minimum Weight)External Calibration Weight Range for Span Calibration 95 to 220.00090 g

(200g)Calibration Weight Built-in *1 Input/Output Terminal RS-232C (D-sub9P plug) USB host (Type A) USB device (Type B) Ionizer *1 Minimum display 0.01mg models provide two internal weights as standard.

*2 Be compliant with USP Chapter 41. This is the tested value by the weight of the balance’s capacity of 5% (or 5 grams’ weight). In the case of the AP225W, the results are for tests carried out with the optional internal windbreak plate applied. The minimum weight value is affected by the installation environment, so it is necessary to measure it in the actual environment of use.

*3 The response time for displaying 90% of the added sample amount value in trace measurements (from 1mg)

*4 The response time value is typical.

*5 Non-condensing